| Unit | SMG-2013 | SMG-2615 | SMG-3217 | Customized | |

| Table Size | mm | 2000*1300 | 2600*1500 | 3200*1700 | |

| Max. Die Weight | T | 6 | 8 | 15 | |

| Min. Daylight | mm | 300 | 300 | 350 | |

| Max. Daylight | mm | 1100 | 1100 | 1500 | |

| Max. Load Capacity on Upper Platen | T | 3 | 3.5 | 7 | |

| Weight of Machine | T | 12 | 15 | 20 |

In the process of mold making, the separation of the mold is indispensable. In the process of mold tryout and testing, the upper and lower molds need to be separated first, then the upper and lower molds are available to be cleaned, repaired, and maintained separately, so the separation of the mold plays an indispensable role.

Siemens PLC System

SXKH has more than 10 years’ experience to use PLC system in Die spotting press. We use new S7-1200 Version as the standard configuration of the Press.

*Equipped with the PLC system

*Remote control module is optional

*Control and monitor press

*All the parameters can be settled and saved

*Memory function available-Mold database

*A wide variety of signal modules for input and output

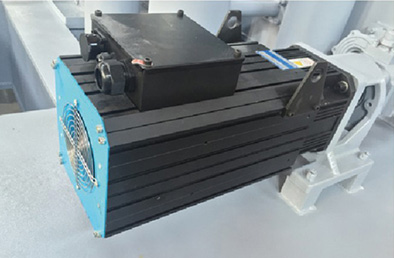

Hydraulic Servo System

*Servo system provides more economical way to operate die splitter (60% energy saving) and provides much better stabilizing force.

*Provide much better stable holding force.

QDC-Quick Die Change System (Optional)

We will provide additional two ways to reduce mold separation time

*Electro-permanent magnetic working table

*Hydraulic clamps